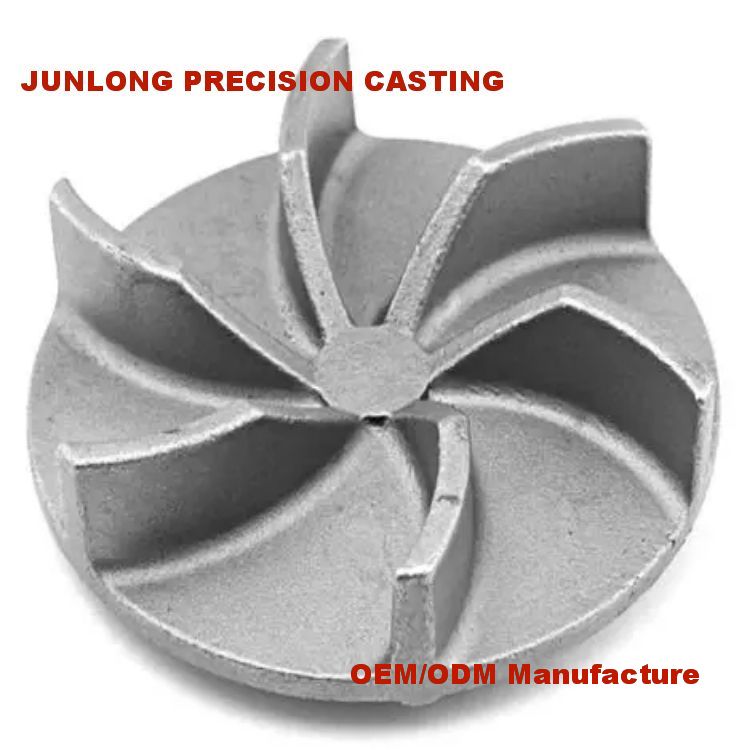

Automotive & Truck Components: Precision Casting Excellence by Weifang Junlong

Weifang Junlong Precision Foundry is revolutionizing the automotive and commercial vehicle industry with its advanced precision casting solutions. Specializing in investment casting (lost wax casting) and silica sol composite processes, we manufacture critical components including engine blocks, transmission housings, and suspension parts with unmatched dimensional accuracy (CT7-CT9 per ISO8062).Our 20,000-ton annual production capacity supports global OEMs with:

- High-strength alloy components

- Weight-optimized designs

- Corrosion-resistant surface treatments

- Complete machining services

Certified to IATF 16949 and ISO 9001, our foundry combines automated production lines with rigorous quality control, including spectral analysis and X-ray inspection. From prototype to mass production, we deliver components that meet or exceed ASTM, DIN, and GB standards.2. Heavy Machinery & Construction Equipment SolutionsWeifang Junlong's precision casting expertise powers the world's most demanding construction and mining applications. Our water glass composite casting process produces durable components for:

- Excavator undercarriages

- Drilling equipment

- Crane mechanisms

- Earthmoving attachments

Key advantages include:

- Wear-resistant alloys for extended service life

- Large-part capability (up to 200kg)

- Custom heat treatment options

- Comprehensive NDT testing

With 8 patented processes and a team of 25+ engineers, we develop innovative solutions that withstand extreme operating conditions while maintaining precise tolerances.3. Energy Sector: Reliable Components for Oil, Gas & Power GenerationJunlong Precision Foundry delivers mission-critical components for energy infrastructure, including:

- Valve bodies and pump housings (API 6A compliant)

- Turbine blades and brackets

- Drilling equipment components

- Power transmission parts

Our technical capabilities feature:

- High-pressure rated designs

- Corrosion-resistant materials

- Cryogenic service alloys

- Complete machining and finishing

The UL-certified facility utilizes advanced dewaxing casting technology and maintains stringent quality protocols to ensure component reliability in the most challenging environments.4. Transportation: Marine & Railway Component SpecialistsFrom propeller hubs to rail couplers, Junlong's precision cast components keep global transportation systems moving. Our offerings include:

- Marine-grade stainless steel castings

- Fatigue-resistant railway components

- Lightweight aluminum solutions

- Custom corrosion protection

Benefits to manufacturers:

- Reduced part weight without sacrificing strength

- Improved fuel efficiency

- Extended maintenance intervals

- Compliance with international maritime and rail standards

5. Green Energy & Infrastructure: Sustainable Casting SolutionsJunlong is at the forefront of renewable energy support with precision-cast components for:

- Solar tracking systems

- Wind turbine assemblies

- Electrical infrastructure

- Architectural hardware

Our sustainable manufacturing approach features:

- Eco-friendly production processes

- Recyclable material options

- Energy-efficient melting technologies

- Long-lasting weather-resistant finishes

With rapid 45-day turnaround times and flexible order quantities, we help green energy projects stay on schedule and budget.Each 1000-word article would expand on these themes with:

- Detailed case studies

- Technical specifications

- Customer testimonials

- Process diagrams

- Quality assurance protocols

- Market trend analysis

The content can be tailored for specific trade publications (e.g., Foundry Management & Technology for automotive, Energy Global for oil/gas) while maintaining consistent branding and messaging about Junlong's capabilities.